A Global Leader In Nuclear Robotics

With more than a quarter-century of innovation in nuclear robotics, Promation delivers end-to-end solutions that get the reaction your company needs.

Global expertise

Backed by decades of experience, Promation prides itself on award-winning service excellence and innovation solution delivery to the nuclear power plant, advanced reactor, decommissioning, and waste management sectors.

Leveraging our CSA N285.0 and N299.1 quality program, Promations solutions include reactor components/systems, remote tooling, and turnkey automated equipment. Promation enables our customers to minimize operator dose, reduce the potential for human error, and reduce operational costs.

Promation's capabilities extend to the medical isotope and radiopharmaceutical industries, where it develops leading-edge automation and robotics with industry-compliant track and trace software for isotope production, processing, and packaging.

Whether you are looking to solve a complex challenge within a harsh environment, develop and deploy new technologies, or scale production, Promation has you covered.

Nuclear capabilities

Promation Nuclear delivers turn-key tooling solutions to support nuclear plant operations and refurbishment projects. From proof of concept to waste handling, our services cover the spectrum of research, development, testing and engineering custom solutions. We offer:

Promation are tooling experts for nuclear applications. Whether it’s for commissioning new builds or retubing existing facilities, all tooling design and development happens in-house. What’s more, our 3D tooling software is used to stress-test custom designs before they go to print—ensuring your job is done right, the first time.

Our tooling solutions include:

- 3D CAD modelling

- Animated simulations

- Prototype tool testing

- Production tool manufacturing and functional testing

- Steam generator maintenance tooling

- Tool commissioning

- Retube tooling

- On-site technical support

Whether for new nuclear plant builds or refurbishment projects, Promation offers a full suite of customizable manufacturing and fabrication services, backed by decades of engineering experience. All work is completed in-house, to your unique specs.

Our manufacturing and fabrication services include:

- Qualified pressure boundary manufacturing

- CNC and manual machine shop services for medium-sized parts

- Welding and heat treatment

- Assembly and testing area including clean assembly capabilities

- Fully compliant metrology and QA documentation with complete traceability

- Shipping and receiving: 10T crane, parts inspection and quarantine room

The Promation nuclear experts have been designing, building and testing nuclear tools for decades. Our experience includes working with all overseas CANDU customers, including TQNPC in China, KEPCO in Korea, NASA in Argentina, and SNN in Romania.

Our testing services include:

- On-site manufacturing of various testing and validation coupons, used for calibration of fuel channel inspection tools

- Manufacturing of known defect standards, to facilitate the calibration of inspection tools

- Facilitation of micro EDM manufactured samples and intentionally defective parts containing artificial discontinuities

- Production of mimic oxide layers on Zirconium Pressure Tube samples

- Testing systems

Protecting end users in the nuclear industry from defects in equipment is an essential component of the automation business. Our services include vision inspections, 3D scanning and custom tooling to ensure our customers stay up and running, with no disruptions to production or safety protocols.

Promation’s decades of experience in the nuclear industry positions us as an expert in fuel channel replacement for CANDU reactors. Our work contributes to providing safe access to the reactor face for trades working within nuclear plants, while our expertise allows our customers to focus on their core lines of business and minimize downtime.

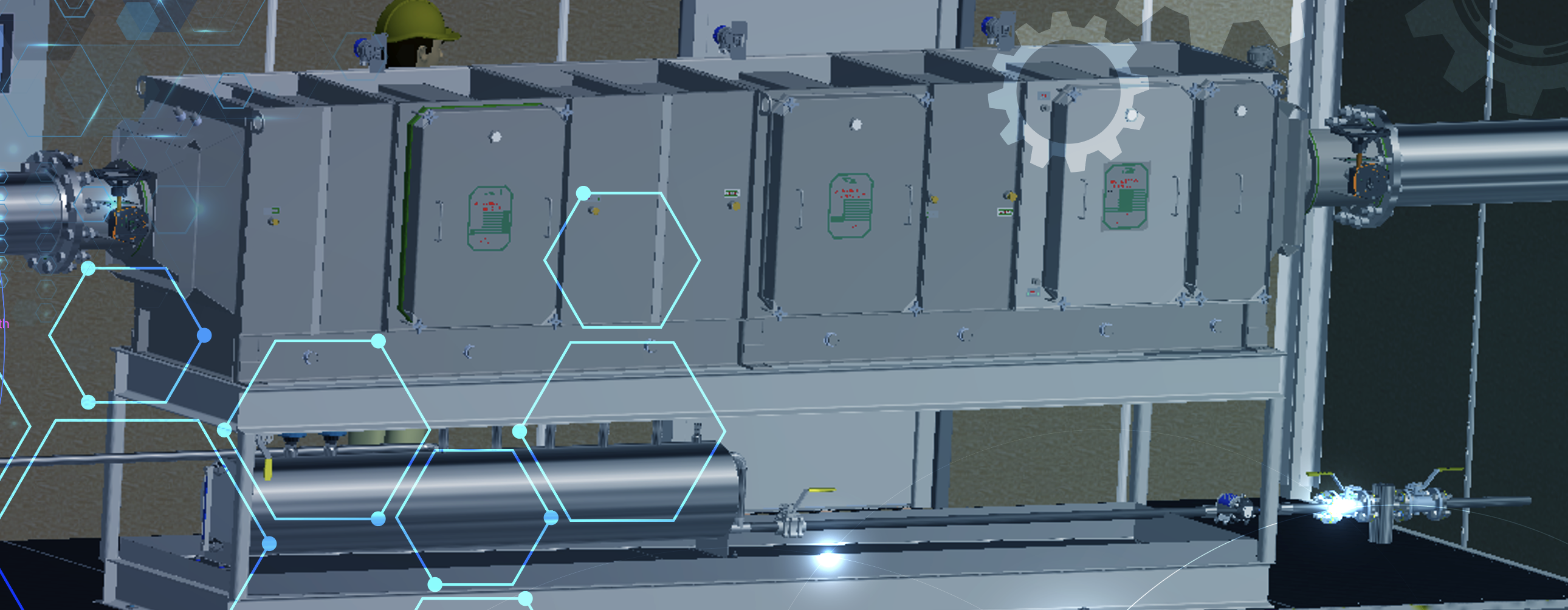

An important part of our CANDU refurbishment offering, Calandria Inspection Tooling uses laser profilometer inspection tools to inspect the condition of equipment prior to calandria tube installation. Promation also offers the expertise to 3D-print prototype tools for proof-of-concept testing prior to use in the field. Promation Nuclear delivers fully engineered, turn-key tooling solutions to streamline nuclear plant operations, new builds and refurbishment projects. Our full scope of services includes research, development, engineering, testing and building.

Promation are your fuel handling experts. Our expertise in nuclear fuel handling enhances plant productivity and provides safer operation using complex, customizable robotics that can rapidly scale up or down in response to volume or radiation protection requirements. You focus on power generation, while our fuel handling systems work in the background to deliver substantial ROI and the peace of mind that comes from knowing your fuel is being handled by an expert team that understands your business.

With decades of expert support for energy producers, radiopharma companies and other nuclear-based industries, coupled with industry-leading robotic solutions, Promation is your choice for radiation source removal and tooling. Our solutions are fully customizable, scalable and adaptable to your own production needs and limitations.

Whether you need ongoing support or assistance in decommissioning a nuclear site, Promation designs and manufactures scalable, customized robotic and automated transfer systems for handling nuclear and radioactive waste. Ask how our waste handling expertise can deliver real results for your business.

Permanent Start-Up Instrumentation (PSUI) for Vertical Flux Detectors

Bruce Power engaged Promation Nuclear to design and build the first-of-a-kind CANDU reactor permanent start-up instrumentation (PSUI) that would be used to replace the traditional temporary start-up instrumentation used to date.

Spent Fuel Bay Water Swap System

A research facility in Ontario that stores used nuclear fuel rods by shielding them with water experienced contamination inside the storage pools of tritiated heavy water.

Whiteshell Laboratories Standpipe Remediation

To safely decommission and remediate its Whiteshell site, Canadian Nuclear Laboratories (CNL) needs remote-operated, bespoke robotics and automation equipment. Promation Nuclear was tasked with the design, fabrication, inspection and testing of two separate nuclear-grade ventilation systems and the standpipe waste retrieval system (SWRS).

Hot Test Rig – Closure Plug Testing System

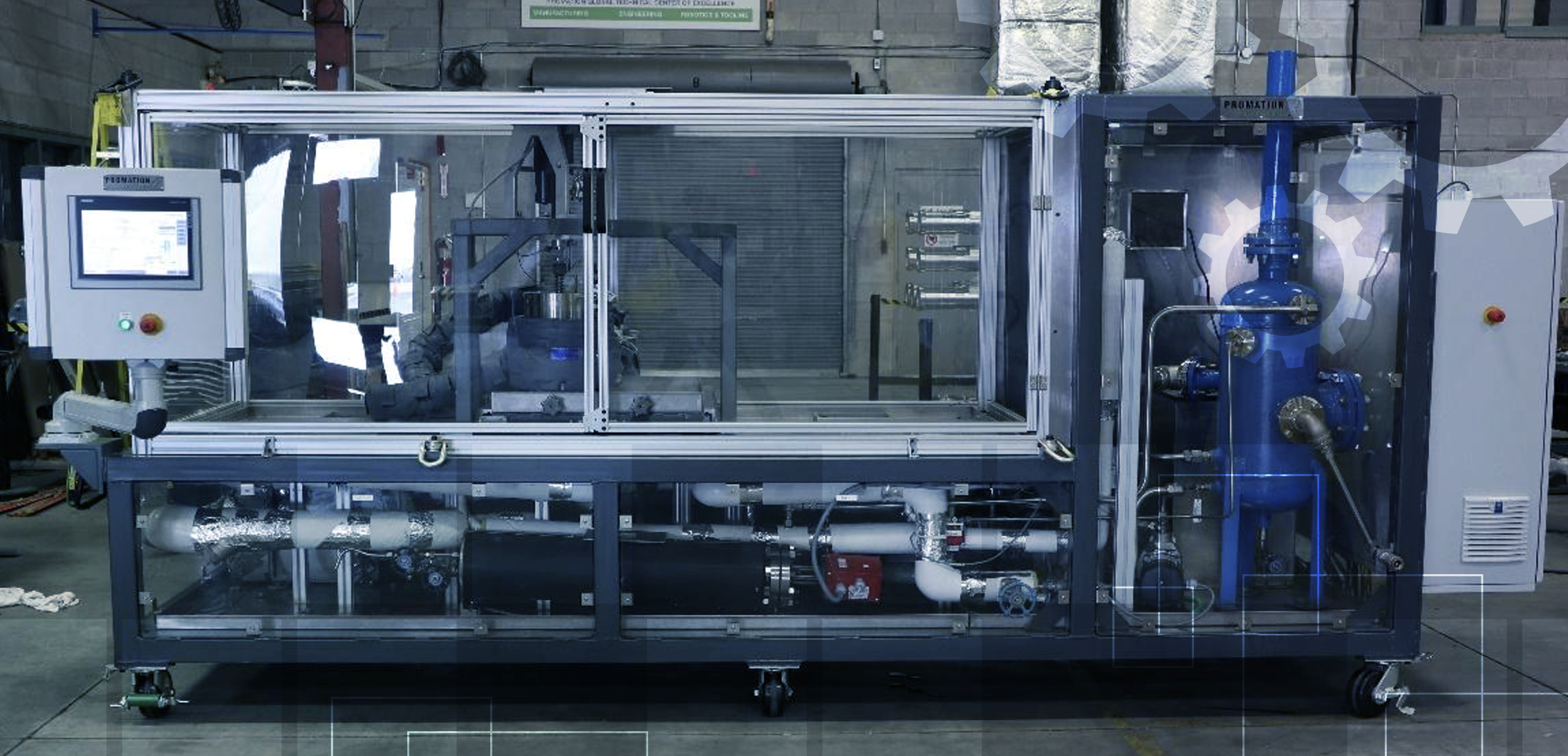

Tier one Nuclear customer approached Promation for the design, TSSA registration, procurement, manufacturing, assembly and commissioning of a hot test rig for performing functional tests of fuel channel closure assemblies used on CANDU nuclear reactors.

Energy-Absorbing Mitigation Crash Pad

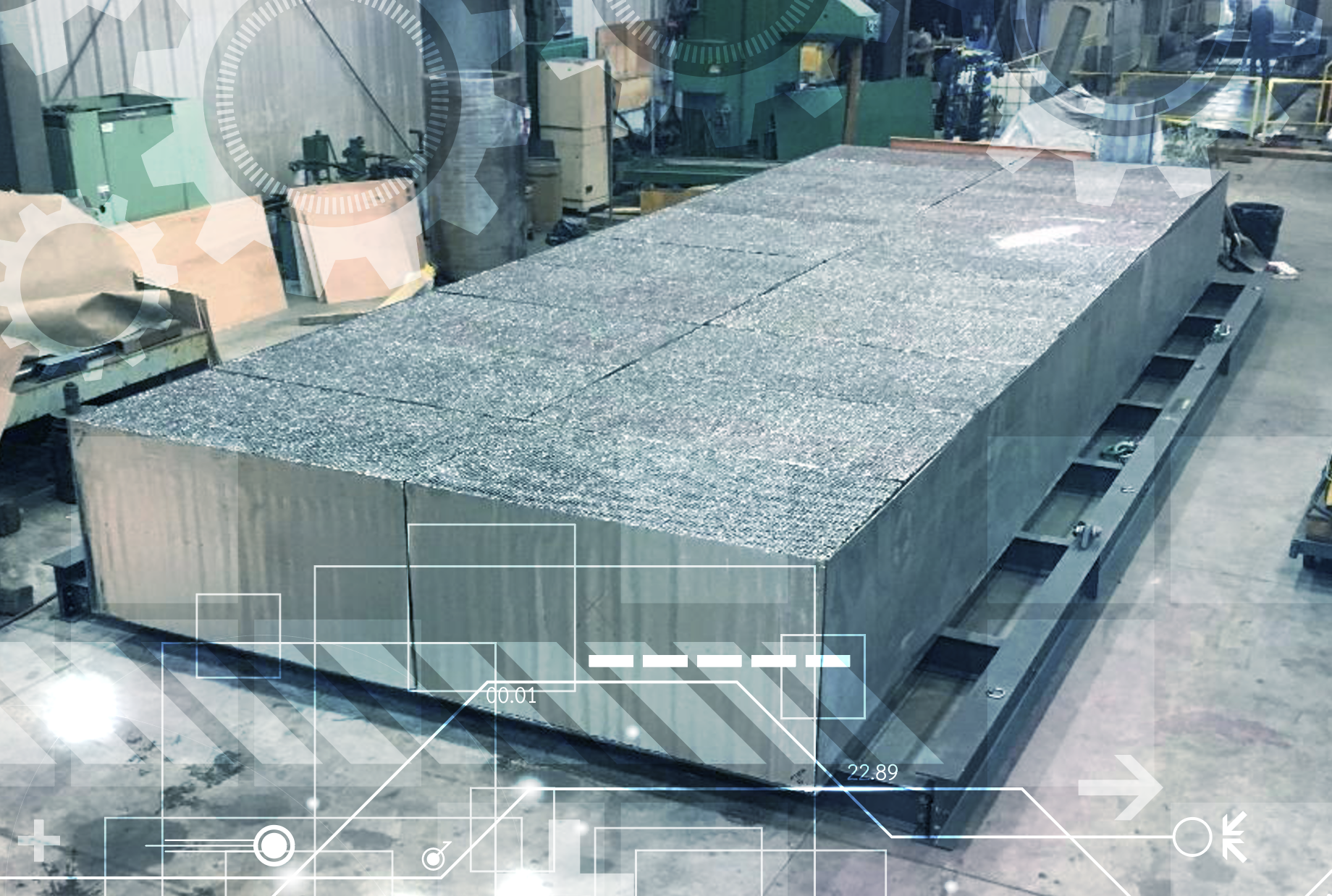

A Tier one supplier to the nuclear industry engaged Promation for the design, engineering, manufacturing, examination and testing of an energy-absorbing crash pad.

Radiation Source (Hot Spot) Removal

One of Ontario’s primary energy utilities had a remote radioactive hot spot that needed to be retrieved, shielded, and disposed of.

Steel-Shielded Storage Containers

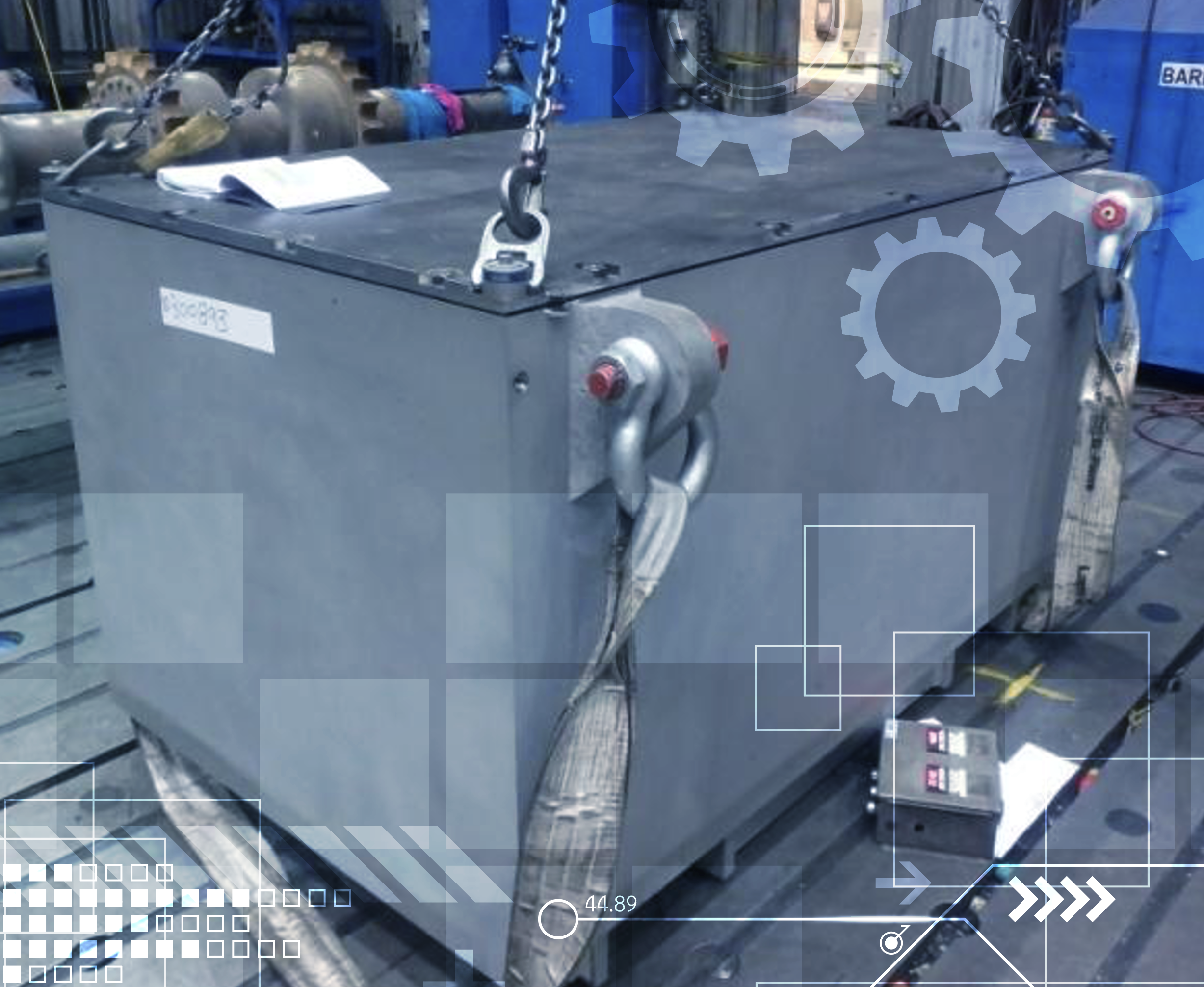

A Tier one supplier to the nuclear industry engaged Promation for the design, engineering, manufacturing, assembly, inspection and test of a shielded storage container for the storage, contamination control, radiation shielding and transportation of its contents from the Retube Waste Processing Building (RWPB) at Darlington Nuclear site to a waste storage facility.

Programs

- Nuclear Pressure Boundary:

- Non Nuclear Pressure Boundary:

- Others:

Nuclear Industry Awards:

- 2022 - OCNI Innovation Award

- 2018 - OCNI Supplier Excellence Award

- 2013 - OPG "Outage Cup Award" for successful Boiler Repair Campaign in high dose areas (in conjunction with BWXT [formerly B&W])

- 2012 - OPG Locking Tabs (in conjunction with B&W)

- 2011 - OPG "Outage Cup Award" for the successful completion of the "Boiler Hot Spot Removal" Remote Tooling development and deployment (in conjunction with Kinetrics)

- 2011 - AECL Supplier Award